26Mar

25Mar

Benefits of Using Safety Light Curtains

What are Safety Light Curtains

Definition and Functionality

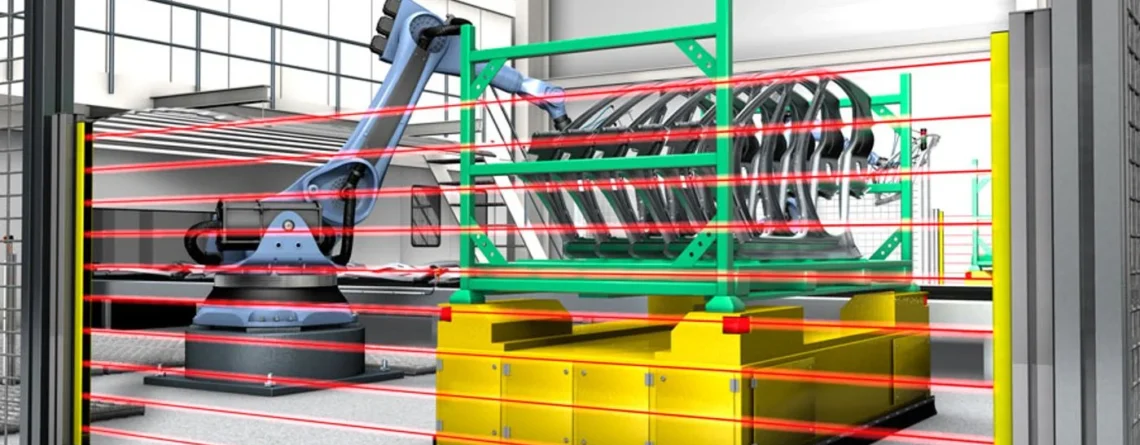

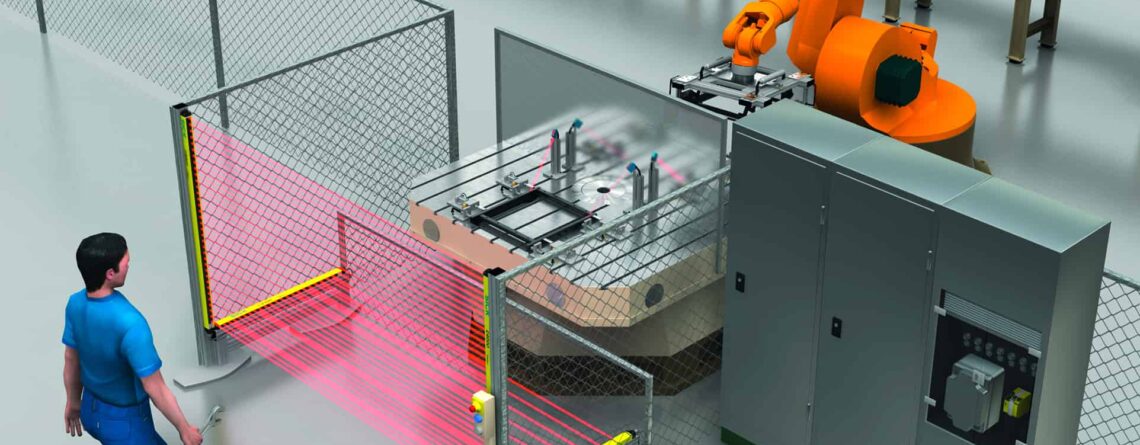

Safety light curtains are advanced presence-sensing devices used to protect personnel from hazardous areas in industrial environments. They operate by emitting infrared light beams across a defined sensing field. When any object—such as a hand or finger—interrupts the...

25Mar

How Do Safety Light Curtains Work?

Understanding Safety Light Curtains

Safety light curtains are advanced presence-sensing devices designed to protect operators from dangerous machinery while allowing safe, hands-free access to work zones. Common in industrial automation, these devices emit a field of invisible infrared beams between a transmitter and receiver....

24Mar

What Are Safety Light Curtains?

How Does Safety Light Curtains Work

Emission of Infrared Beams

Safety light curtains operate by emitting invisible infrared beams across a protected area, usually between a transmitter and a receiver. These beams form a detection grid—when uninterrupted, the system allows the machine to run. If any...

26Sep

Muting Light Curtains. How does Muting Work? Learn NOW.

Overview of light curtains and muting

As discussed in our two previous blog posts, safety light curtains from ReeR are an effective and innovative method to protect workers from hazardous environments. Light curtains...

16Sep

Measured Risks, Invisible Barriers: How ReeR Light Curtains Keep You Safe

SAFETY & MEASUREMENT light curtains overview SAFETY

In manufacturing and automated industries, worker safety is paramount. Machinery that poses hazards during operation must be safeguarded with clear boundaries to prevent accidents. Even in the safest environments, all it takes is an unknowing factory visitor or a...

05Jul