13

What are Programmable Systems, PLC’s and Safety Automation?

In today’s rapidly evolving industrial landscape, prioritizing top-notch safety standards is paramount. Programmable systems have emerged as indispensable tools, offering dynamic solutions to intricate safety challenges. Among these innovations, Venus Automation proudly presents its advanced programmable safety controllers, engineered to revolutionize safety applications across diverse industries.

As industrial automation continues to evolve, the need for advanced control and safety solutions has never been greater. Safety PLCs and Programmable Logic Controllers (PLCs) play a crucial role in modern manufacturing by enabling efficient, flexible, and safe operations. These systems provide a seamless integration of standard and safety functionalities, reducing hardware requirements while ensuring compliance with strict industrial safety regulations.

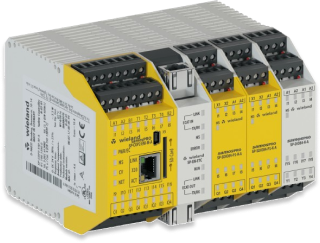

Among the most innovative solutions, ReeR MOSAIC and Wieland SAMOS modular safety controllers offer an all-in-one platform for monitoring and managing safety-critical applications. These controllers replace traditional relay-based systems, improving flexibility and simplifying system architecture. The compact design of compact safety controllers further enhances their adaptability, making them an ideal choice for space-constrained applications.

For industries requiring high-performance automation, Mitsubishi PLCs deliver robust and scalable solutions. Whether utilizing the Mitsubishi FX Series for compact automation or the Mitsubishi Q Series for complex industrial processes, these controllers ensure reliable performance. Additionally, networking solutions such as CC-Link Systems provide seamless communication across automation architectures, enhancing data exchange and system efficiency.

By leveraging these programmable safety and automation solutions, businesses can optimize production, enhance worker safety, and ensure compliance with modern industrial standards.

Key Features & Benefits:

- Integrated Safety and Control: By merging standard and safety-related functions, our controllers eliminate the need for separate safety relay systems, ensuring streamlined operations while upholding the highest safety standards.

- Flexible Programming: With exceptional programming flexibility, users can tailor safety protocols to their unique requirements, ensuring swift adaptation to evolving operational conditions.

- User-Friendly Interface: Our controllers boast an intuitive programming environment, facilitating seamless development, testing, and implementation of safety protocols.

- Advanced Safety Features: Engineered to meet stringent safety standards, our controllers are equipped with advanced features designed to swiftly bring automated processes to a safe state, minimizing accident risks.

- Cost-Effective Solution: By eliminating the need for separate safety relay systems, our controllers offer a cost-effective solution for enhancing electrical safety, reducing overall system costs and maintenance expenditures.

- Easy Integration: Seamlessly integrating with existing automation systems, our controllers preserve system performance while enhancing safety capabilities, ensuring smooth implementation without disrupting ongoing operations.

- Wide Application Range: Suitable for a variety of complex safety applications across multiple industries, including manufacturing, processing, and logistics, our controllers offer versatility and reliability in diverse operational environments.

Expanding on the concept of programmable systems, it’s essential to understand their evolution and significance in industrial automation. Programmable logic controllers (PLCs) have been pivotal in revolutionizing industrial control systems. Originally developed to replace complex relay-based control systems, PLCs have evolved into sophisticated devices capable of managing entire industrial processes.

The versatility of PLCs lies in their ability to be programmed and reprogrammed to perform a wide range of tasks, from simple logic functions to complex process control applications. This adaptability makes PLCs ideal for various industries, including automotive, food and beverage and pharmaceuticals. Moreover, PLCs offer reliability, durability, and scalability, making them suitable for applications ranging from small-scale machines to large-scale industrial plants. Their robust design and built-in safety features ensure uninterrupted operation even in harsh industrial environments.

Advanced programmable safety controllers from Venus Automation are poised to transform electrical safety automation. With innovative features and user-friendly design, these controllers empower businesses to elevate safety standards while optimizing efficiency and cost-effectiveness. Investing in Venus Automation’s programmable safety controllers is essential for staying ahead of safety challenges and safeguarding personnel and assets in today’s dynamic industrial landscape. Discover more about our solutions here and here.

Incorporating PLCs into safety-critical systems, such as those offered by Venus Automation, enhances the overall safety and reliability of industrial processes. By leveraging the capabilities of programmable systems, businesses can not only meet regulatory requirements but also create safer working environments for their personnel.

Integrating Safety PLCs and Monitoring Systems for Complete Safety Control

As discussed, programmable safety controllers like MOSAIC, SAMOS, and advanced Mitsubishi PLCs are transforming how safety-critical systems are managed. But to build a complete and reliable safety infrastructure, these controllers must be paired with effective monitoring components and output devices that ensure accurate system response in real time.

A key component in modern safety systems is the safety PLC. These programmable devices allow custom safety logic, with flexible input/output terminal assignments. Venus Automation offers a variety of models, including the MOSAIC PLC from Reer, Samos PLC from Wieland, and GEMNIS PLC from Pizzato—each delivering advanced and reliable safety functionality.

Where complex programmability is unnecessary, alternative options such as the safety relay range are available. This includes standalone relays, time-delay relay, speed-monitoring relay, standstill monitoring and timer, PCB relay, relay expansion modules, and control relays like the emergency stop relay, safety edge relay, light curtains relay, and two-hand control relay. These options provide effective and application-specific safety responses.

Essential manual inputs such as the emergency stop remain integral to any safety architecture, despite lacking an automatic safety input. Venus Automation supplies complete solutions including emergency stop accessories, pushbuttons, two-hand stops, and specialized devices like the rope pull emergency stop. For modern installations, wireless safety systems, including wireless emergency stop units, remote controls and accessories, are also available.

Critical integration elements such as contact blocks are supplied to ensure seamless circuit connections. Additional safety monitoring components include the safety encoder, which monitors motor speed, and interlock devices such as tongue solenoid interlock switch and electro-magnetic switches. For more complex safety guarding, multifunctional gatebox units provide a consolidated interface, easily mounted on protective enclosures like concertina guards.

Access restriction and control can also be achieved through electronic key systems, ensuring machinery operates only under authorized conditions. Finally, for output-side protection, safety contactors and pneumatic safety valve solutions are available to ensure reliable machine stoppage when hazardous conditions are detected.

Click to view product range