Trapped Key Systems

Trapped Key Interlocks: Enhancing Industrial Safety and Efficiency Trapped key interlocks are a proven safety mechanism used to control access to hazardous machinery by enforcing…

Trapped Key Interlocks: Enhancing Industrial Safety and Efficiency

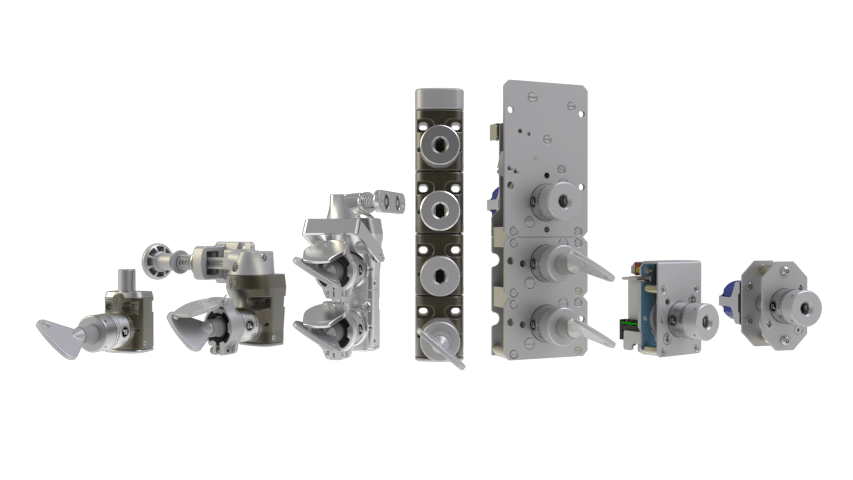

Trapped key interlocks are a proven safety mechanism used to control access to hazardous machinery by enforcing a strict sequence of operations. These mechanical systems use a key exchange process to ensure that machines or processes cannot be accessed or restarted unless all safety conditions are met. The method provides a fail-safe, electrical isolation-independent solution that eliminates reliance on operator judgment alone.

This interlocking method is especially beneficial in:

- Industrial automation requiring controlled access through gates or guard doors

- Valve interlock systems for chemical, energy, or water applications

- Maintenance scenarios involving circuit breakers, control panels, or energy supply lockouts

Designed for harsh environments, trapped-key interlocking systems feature rugged materials such as stainless steel and robust mechanical units that resist wear and operate reliably in dusty, wet, or high-vibration settings. The ability to enforce a safe sequence makes them ideal for preventing human error, ensuring compliance with safety regulations, and supporting safe access across critical processes.

With their cost-effective, modular design, and availability in customisable solutions, trapped key interlocks have become an essential component of modern safety applications, balancing operational efficiency with uncompromised protection.

Key Components of Trapped Key Interlocks

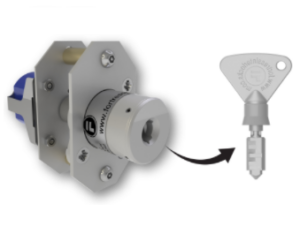

HST-K System Key

The HST-K system key is the core element in any trapped key interlocking system. Each key is uniquely coded to operate a designated interlock, ensuring that only the correct sequence is followed. Once inserted into a device—such as a guard lock, valve interlock, or circuit breaker interlock—the key remains trapped until the corresponding action (like power-off or valve closure) is completed.

Made from stainless steel or industrial-grade alloys, these keys are highly durable and suited for harsh environments where reliability is critical. In more complex systems, multiple HST-K keys may be assigned to a key exchange unit to manage multi-step isolation and safe access control across different zones.

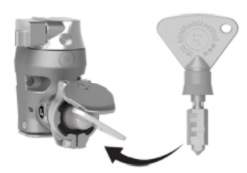

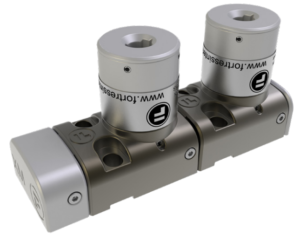

HST-LS Switchgear Interlocks

HST-LS switchgear interlocks are designed to fit directly onto switchgear equipment, such as rotary switches, disconnects, or circuit breakers. These interlocks mechanically prevent the operation of switchgear components unless the appropriate trapped key is present, ensuring electrical isolation before access can be granted.

Ideal for control panel safety, the HST-LS series is compact, adaptable, and suitable for both retrofitting and integration into new installations. These devices help maintain safety integrity by physically enforcing lockout before maintenance or inspection can proceed.

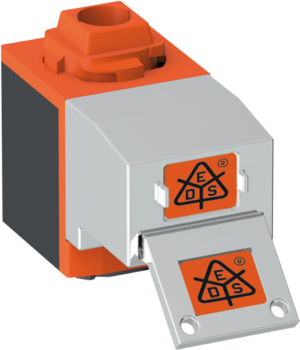

Solenoid-Released Control Switches

Solenoid-released control switches combine mechanical interlocking with electrical control logic, making them suitable for applications requiring real-time status feedback. The solenoid locks the key in place until an external signal—such as power-down confirmation or a process condition—is verified.

These switches are commonly used in high-risk industrial automation settings where hazardous energy sources must be fully discharged before machine access is allowed. They are especially useful when a safe sequence must include both mechanical and electrical confirmation steps.

Mechanical Time Delay Units

Mechanical time delay units introduce a delay between power-down and key release, allowing rotating equipment or processes to come to a complete stop before access. These devices are crucial for machines with run-down times, such as motors, flywheels, or pressure systems.

Time delay units ensure that operators cannot remove the access key until the delay period has elapsed, reinforcing safe access protocols and preventing premature entry into hazardous zones. As a non-electronic solution, they are highly reliable in demanding environments where electrical control may be limited.

Benefits of Implementing Trapped Key Interlocks

Improved Safety Compliance

Trapped key interlocking systems are specifically designed to meet strict safety regulations and standards for controlling access to hazardous machinery. By enforcing a safe sequence of operations, they prevent unauthorized entry, accidental restarts, or premature energy reconnection—common causes of workplace injury.

These systems support compliance with international safety directives such as ISO 14119, IEC 60204, and machinery-related safety integrity requirements. Because the system is mechanical, it provides reliable protection even during power loss or electrical isolation, ensuring continuous risk mitigation.

Operational Efficiency and Reduced Downtime

Trapped key interlocks improve workflow by streamlining access control during routine maintenance, inspection, or process changeovers. With clearly defined sequences and key exchange mechanisms, operators spend less time verifying safety conditions or waiting for system clearance.

This predictable, repeatable process reduces the likelihood of human error and speeds up reactivation once safety conditions are met. In high-output environments, this translates to minimized machine downtime, more efficient lockout/tagout procedures, and better coordination between maintenance and production teams.

Cost-Effective Risk Management

Compared to complex electrical systems or programmable safety logic, mechanical interlocks offer a more cost-effective solution for many applications. They require minimal wiring, no software configuration, and virtually no ongoing calibration. The robust design of components such as bolt modules, access locks, and mechanical time delay units also ensures long service life with little maintenance.

For facilities managing dangerous equipment, valve interlocks, or infrequent yet critical energy isolation events, implementing trapped key systems reduces both liability and capital expenditure—making them an ideal investment in long-term risk management.

Integration and Compatibility

Using STEP Files for Product Details

To simplify engineering and system design, many trapped key interlock components are available as downloadable STEP files. These 3D CAD files allow designers and engineers to integrate interlock models directly into their system layouts, control panels, or mechanical assemblies during the planning phase.

With STEP files, teams can:

- Verify mechanical fit and clearance

- Align mounting points and access door orientation

- Validate interlock compatibility with control devices, valve enclosures, or electrical cabinets

By incorporating these files early in the process, users reduce installation time, avoid costly revisions, and ensure the chosen key system fits precisely within the intended application.

Seamless Integration into Existing Systems

One of the key advantages of trapped key interlocking systems is their modular design, which supports straightforward retrofitting and expansion. Whether applied to circuit breakers, valve lockouts, or machine guarding, these devices can be installed alongside or in place of existing safety switches, mechanical latches, or electrical isolation points.

Integration benefits include:

- Compatibility with mechanical locks, control panels, and access locks

- No need for complex electrical wiring

- Simple addition of time delay units, key exchange boxes, or solenoid-released locks as process requirements evolve

Because the system relies on physical key movement, it functions independently of software or network protocols, making it ideal for operations seeking to enhance safety without the complexity of advanced electronics. Whether used in a new installation or as part of a machine upgrade, these systems maintain full functionality and safety integrity.

Enhancing Safety Protocols with Interlocks

Preventing Unauthorized Access

Trapped key systems are highly effective in preventing unauthorized access to hazardous machinery and energy sources. By design, these systems physically restrict entry until a specific key sequence is followed—ensuring only trained personnel who possess the correct key can unlock access points such as guard doors, control panels, or valve isolation stations.

This mechanical restriction helps eliminate:

- Bypassing of safety guards

- Entry during live or unsafe machine conditions

- Unintended machine restart during maintenance or inspection

The simplicity and reliability of mechanical locks, even in harsh environments, make them a preferred solution for industries where access safety is non-negotiable and electrical override risks must be avoided.

Ensuring Safe Operational Sequences

Beyond controlling access, trapped key interlocks enforce a clearly defined sequence of operations that must be completed in order. This ensures that hazardous energy is safely isolated and machinery is rendered inert before personnel can proceed with maintenance, repairs, or entry.

For example, a typical safe sequence might include:

- Isolating circuit breakers or hydraulic energy

- Releasing a key only once isolation is verified

- Using that key to access a door interlock, valve lock, or key exchange unit

- Preventing machine restart until all keys are returned to their original positions

These enforced sequences help minimize human error, maintain safety integrity, and support a culture of accountability across teams. In more complex applications, key exchange boxes or mechanical time delay units can be added to address run-down times or multi-zone coordination, further reinforcing safe operating procedures.