At our company, we are proud to offer a wide range of standalone safety relays from renowned brands such as Wieland and DOLD. These brands…

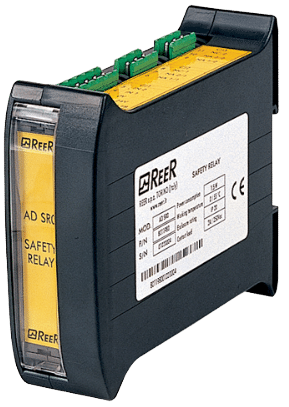

At our company, we are proud to offer a wide range of standalone safety relays from renowned brands such as Wieland and DOLD. These brands are known for their exceptional quality, reliability, and innovation in the field of safety automation. By partnering with these trusted manufacturers, we ensure that our customers have access to the latest advancements in safety relay technology.

What are Standalone Safety Relays?

Standalone safety relays, also known as safety control relays, are vital components in machinery and industrial systems that ensure the safety of personnel and equipment. They are specifically designed to monitor and control safety functions, such as emergency stops, safety gates, light curtains, and two-hand control systems.

Functionality and Operation

Standalone safety relays act as a critical intermediary between the safety devices (e.g., sensors, switches) and the machine’s control system. Their primary function is to detect potentially hazardous conditions and initiate appropriate safety measures to prevent accidents or injuries.

These relays employ redundancy and advanced logic algorithms to achieve a high level of reliability and safety. They typically feature multiple input channels for connecting various safety devices and multiple output channels to control the machine’s actuators or initiate emergency shutdowns.

The operation of a standalone safety relay involves continuous monitoring of input signals from safety devices. If any of these signals indicate an unsafe condition, the relay will immediately interrupt the machine’s control circuit, triggering a safe state or emergency stop. This rapid response ensures that dangerous situations are addressed promptly, minimizing the risk of harm.

Key Features of Standalone Safety Relays

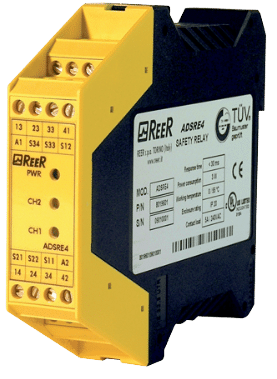

Dual-Channel Architecture: Standalone safety relays often incorporate two independent channels that function in parallel, providing redundancy for enhanced safety. Both channels monitor the same inputs and compare their outputs to detect faults or failures. If a discrepancy is detected, the relay will automatically activate the safety measures.

Forced-Guided Contacts: Safety relays employ forced-guided contacts, ensuring that the outputs change state in a controlled and predictable manner. This feature prevents the occurrence of “welded” or “stuck” contacts, which could compromise safety.

Self-Checking and Diagnostics: Many standalone safety relays offer self-checking and diagnostic capabilities to detect internal faults, such as component failures or wiring faults. These features help ensure the relay’s integrity and enable timely maintenance or replacement.

Configurability and Flexibility: Safety relays often come with configurable parameters and settings, allowing customization to meet specific safety requirements. This flexibility enables seamless integration into different machines and applications.

Monitoring and Status Indication: Safety relays may provide visual indicators or status outputs to indicate the operational status, fault conditions, or diagnostic information. These features aid in troubleshooting, maintenance, and overall system monitoring.