What are Rope Pull Switches? Definition and Function Rope pull switches are emergency stop devices designed to shut down equipment when a rope is pulled…

What are Rope Pull Switches?

Definition and Function

Rope pull switches are emergency stop devices designed to shut down equipment when a rope is pulled from any point along its length. Unlike standard E-Stops, these switches cover large areas, making them ideal for conveyor systems and long machinery lines.

How They Enhance Safety

By providing emergency stopping across extended distances, rope pull switches allow for fast response to hazardous situations, ensuring worker protection in industrial automation environments.

Key Features of Industrial Rope Pull Switches

Long Reach Emergency Access

These switches are designed for rope lengths up to 100 meters, offering wide-area coverage in large-scale facilities.

Tension Monitoring Systems

Advanced models include tension indicators and built-in safety mechanisms to detect slack or over-tensioning, minimizing false triggers or failure to detect.

Robust Mechanical Design

Made with durable enclosures (IP65/IP67 rated), these switches resist dust, water, and mechanical impact, suitable for harsh industrial environments.

Types of Rope Pull Switches

Manual Reset vs. Automatic Reset

-

Manual reset switches require a deliberate action after activation.

-

Automatic reset models restore functionality once the rope is returned to normal tension.

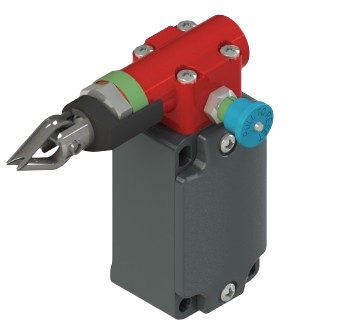

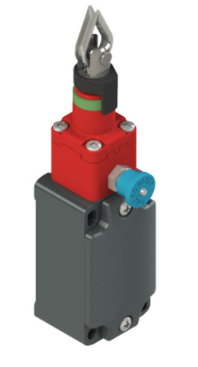

Compact Rope Pull Switches

Designed for space-constrained installations, offering full safety functionality in a smaller footprint.

Dual-ended Systems

Allow tensioning from both ends, ensuring uniform response and balanced load along longer conveyor systems.

Broader integration with Safety & Automation Systems

In modern industrial environments, safety rope pull switches are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. The safety PLC in particular has a major role in managing the emergency stop rope pull, or other safety devices such as the emergency stop button or two-hand stations.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Applications Across Industries

Conveyor Belt Systems

The most common application, enabling quick stop across the full length of the belt, preventing injuries and product damage.

Packaging and Processing Lines

In fast-paced environments, operators can access emergency stops instantly, reducing downtime and risk.

Food, Mining, and Heavy Industries

Rugged rope pull switches offer reliable operation in dusty, wet, or corrosive settings, critical for industrial safety compliance.

Installation and Maintenance

Mounting Options and Tensioning

Proper mounting ensures correct rope tension and reliable actuation. Many models include LED indicators or mechanical flags to show switch status.

Periodic Testing and Inspection

Routine checks help identify mechanical wear, misalignment, or loss of tension, which could affect performance in emergency situations.

Compliance and Safety Standards

Rope pull switches must comply with:

-

ISO 13850 (Emergency Stop Function)

-

EN 60947-5-5 (Electromechanical Control Devices)

-

AS 4024.1604 (Australian standard for Emergency Stop design)

Competitive Advantages of Venus Automation Rope Pull Switches

-

Broad product range from leading brands like Pizzato and IDEM

-

Models with LED indication, reset buttons, and M12 connectors

-

Custom solutions for hazardous area classification or ATEX zones

Frequently Asked Questions (FAQ)

Q1: What is the maximum rope length supported?

A: Most models support up to 100 meters, but some can extend further with proper tensioning kits.

Q2: Can rope pull switches be used outdoors?

A: Yes, if they have appropriate IP ratings (e.g., IP67) for water and dust resistance.

Q3: Are they compatible with safety relays?

A: Absolutely. Rope pull switches are often integrated with safety relay modules to enable machine safety circuits.