What Are Blocking Devices? Definition and Role in Industrial Safety Blocking devices are mechanical components within the field of trapped key systems that physically prevent…

What Are Blocking Devices?

Definition and Role in Industrial Safety

Blocking devices are mechanical components within the field of trapped key systems that physically prevent access to hazardous zones until a specific sequence of operations has been completed. These devices form a vital part of industrial safety systems, ensuring that dangerous machinery or environments cannot be accessed unless it’s completely safe to do so. Unlike traditional lockout/tagout methods, blocking devices offer a fail-safe, mechanical method of enforcing safe procedures, even in harsh environments.

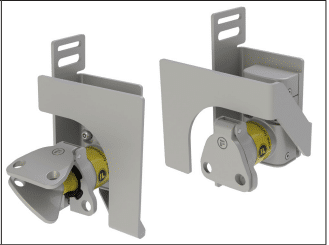

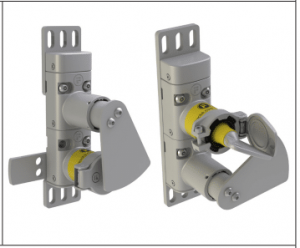

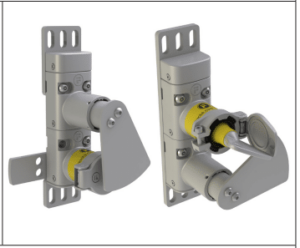

Core Components: Key, Lock, and Blocking Mechanism

A typical trapped key interlock system includes components such as a key, a lock, and a blocking device. The blocking mechanism is directly engaged by the key and is designed to hold or release mechanical parts, such as doors, gates, or actuator arms. When the key is removed from one part of the system, it can be inserted into another, triggering a mechanical sequence that either grants or restricts access. In some systems, a safety key is mandatory to initiate or conclude the locking process, ensuring personnel protection.

How Blocking Devices Prevent Hazardous Access

Trapped key blocking devices operate on a mechanical logic principle—ensuring that actions happen in a controlled order. For example, a machine’s power supply must be fully disconnected before access to its internal parts is granted. Blocking devices like bolt locks or access interlocks physically hold doors shut or prevent motion until the correct key is inserted, confirming that all safety conditions have been met. This eliminates the risk of unexpected start-up and reinforces access control procedures.

Key Benefits of Using Blocking Devices

Enhancing Functional Safety and Compliance

Blocking device interlock systems are compliant with international safety standards such as ISO 14119 and ISO/TS 19837. By using mechanical interlocks and blocking devices, manufacturers can achieve higher Safety Integrity Levels (SIL) and Performance Levels (PL), reducing the risk of human error and enhancing workplace safety. These systems are ideal for use with a wide range of electrical equipment and control setups.

Eliminating Electrical Overrides with Mechanical Control

Mechanical blocking devices eliminate the possibility of bypassing safety controls through electrical manipulation. In systems where electrical interlocks could be overridden, trapped key systems ensure that access control is entirely physical—bolstering reliability in hazardous energy control. For extra safety, interlock safety contacts may also be used to signal the state of the lock to external systems.

Protecting Personnel Through Controlled Access

Blocking devices enforce a strict access sequence that guarantees operators and maintenance personnel are not exposed to active machinery. By retaining the key in the power switch or isolator until machinery has stopped, these devices ensure only authorized personnel can gain entry to high-risk zones. This is critical in body access applications and Aisle Access points where physical proximity to dangerous components is common.

Types of Blocking Devices for Trapped Key Systems

Bolt Locks and Key Exchange Units

Bolt locks are commonly used to hold movable guards, actuators, or machine components in place until all safety requirements are fulfilled. Key exchange units facilitate the safe transfer of control by releasing one or more keys only after the initial key is inserted, ensuring the sequence of operations is preserved. These components are often built from robust materials, including stainless steel or metal alloy housings, offering durability in harsh environments.

Access Locks and Key Transfer Blocks

Access locks are installed on doors, hatches, or panels and prevent opening until the correct key is inserted. Key transfer blocks work as intermediate stations, making it possible to split control across multiple zones or devices while maintaining mechanical interlock integrity. A wide variety of configurations and customisable solutions are available to suit different custom applications.

Solenoid Release Units and Interlock Switches

Solenoid-controlled blocking devices combine electronic signals with mechanical interlocks, where the key is only released or accepted when a signal condition (e.g., power-off confirmation) is met. These hybrid designs are ideal for integrating trapped key systems with Safety PLCs or modern control architectures. For further safety, some systems incorporate safety contact monitoring or integrate with photoelectric sensors and beam sensors to detect human presence through a beam of light.

Industry Applications of Trapped Key Blocking Devices

Manufacturing and Machine Guarding

Trapped key systems are widely used across manufacturing plants for guarding access to cutting machines, robotic cells, conveyor belts, and other dangerous machinery. Blocking devices provide machine guarding solutions that maintain a consistent level of safety across high-throughput environments. They are especially effective in custom applications involving a variety of interlocks and control devices.

Electrical Switchgear and Robotics Safety

In electrical switchgear, blocking devices prevent access to live panels unless isolators are fully engaged and locked. In robotic applications, these devices ensure the robot is powered down and motionless before operators can enter the enclosure or perform maintenance. Photoelectric sensors may be added as an extra layer of safety in robotic cells.

Conveyor and Valve Interlocking Systems

For conveyor systems, trapped key interlocks and blocking devices maintain synchronization between different motion zones. In valve control applications, especially within chemical or process industries, trapped key blocking mechanisms prevent unsafe valve operations or cross-contamination during maintenance. Systems may also include safety contact and sensor feedback to alert users of any misalignment or breach.

Choosing the Right Blocking Device

Key Selection Criteria: Type, Access, and Reset

Choosing a suitable blocking device depends on factors such as the type of motion being controlled, access frequency, and whether manual or solenoid-based reset is needed. Bolt locks are ideal for physical barriers, while solenoid release units are better suited for systems requiring PLC communication. For high-traffic applications, devices with stainless steel or metal alloy construction offer longer life cycles.

Integration with Existing Safety Systems

Trapped key interlock blocking devices can be retrofitted into existing machine safety frameworks or designed into new builds. Compatibility with other mechanical interlocks, safety relays, and control architectures ensures a modular, scalable safety solution. They can be applied in a wide range of industrial settings with a variety of applications.

Custom Trapped Key Interlock Solutions

Many manufacturers offer customizable trapped key systems tailored to specific industry needs. From adjustable key exchange units to sector-specific blocking mechanisms, these bespoke solutions help businesses meet machine guarding and hazardous energy control requirements efficiently and effectively. Whether it’s a rugged stainless steel device for a harsh environment or a compact solution for aisle access, a wide range of interlocks is available to ensure reliable, safe, and precise access control.